From concept development to production scale-up, EV manufacturers face several key considerations as they navigate their journey. Can we engineer a vehicle that keeps our unique designs whilst meeting stringent safety standards in different regions? How can we do this efficiently, creating a CAE environment that scales as we grow?

With our comprehensive portfolio of services and products built upon deep industry experience and learning, we can provide the tools and support you need to accelerate your vehicle development process and develop a flexible and agile CAE approach catered to each stage of your company’s evolution.

Automotive CAE Consultancy

In realising their concepts, EV manufacturers need a head start in acquiring know-how and bringing CAE expertise onboard that can leverage a powerful and proven automotive crash and structural dynamics environment. As a trusted advisor to the automotive industry, we advise on structural design and material selection, and can help with navigating the appropriate regulations as part of your CAE, safety and materials teams.

- We have a global team of CAE analysts that are expert in structural and crash safety simulations with knowledge of the latest safety regulations and protocols to ensure your vehicle meets all occupant and pedestrian safety standards. We undertake analysis of:

- Durability

- Noise, harshness and vibration

- Occupant safety

- Interior systems

- Pedestrian safety

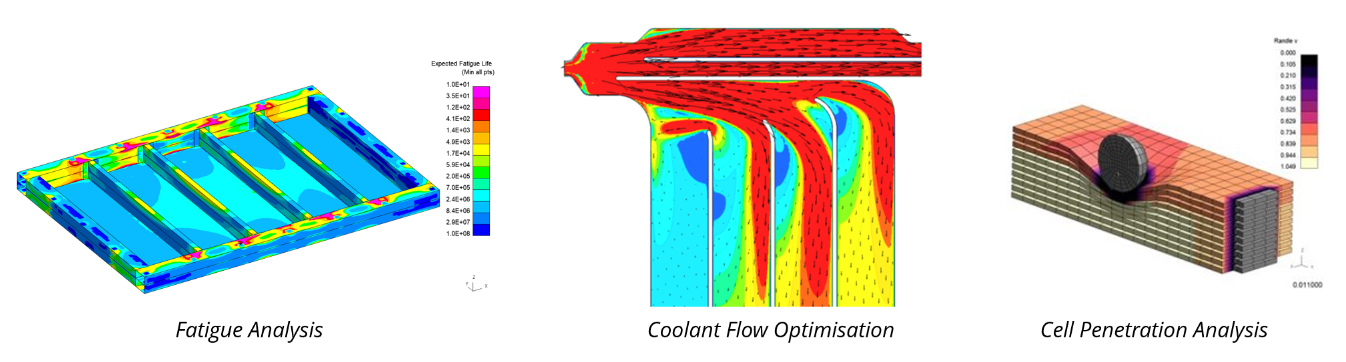

- We have in-depth experience of battery analysis, including:

- Impact and shock

- Vibration and fatigue

- Charge induced swelling

- Cooling

- Multi-factor optimisation, including battery floor and enclosure

- We employ the latest techniques developed from internal research to stretch the possibilities of battery analysis in LS-DYNA.

Oasys LS-DYNA Environment

We utilise the Oasys Suite in our consulting work. This market-leading pre- and post-processing software is developed specifically for LS-DYNA and used extensively by leading automotive manufacturers around the world.

- An integrated suite of software with tools that enable different safety assessments to be automated through the entire analysis workflow, with a scripting environment supporting integration with your processes:

- Utilise the complete set of LS-DYNA capabilities without compromise in Oasys PRIMER, from the class-leading crash and injury analysis capabilities to the coupled multi-physics capabilities for studying multiple battery abuse scenarios

- View, examine and manipulate your model easily using Oasys D3PLOT. Need to share your model? Oasys D3PLOT Viewer, our new web-based platform, empowers you to collaborate on 3D models with anyone – internal colleagues or external suppliers and partners.

- Examine and present your output using Oasys REPORTER. With its built-in templates and scripts ready for an extensive set of international safety protocols, your CAE analysis can be more automated and efficient.

- Oasys SHELL streamlines your use of the suite with automated job submission to accelerate your CAE process and improve your efficiency

- Extensive training and tutorials by our in-house CAE experts provide your team with the knowledge and skills needed to bring your designs to life.