Software Used on this Project

Project Overview

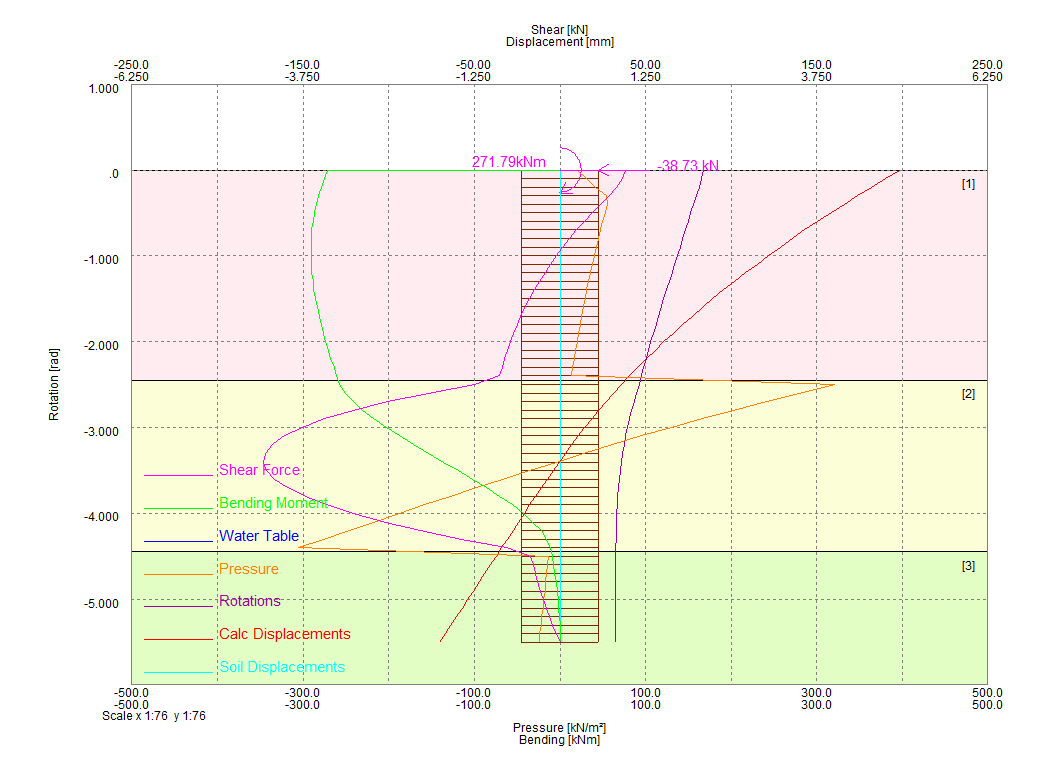

Arup’s Ground Engineering team in Melbourne utilised comprehensive piling software, Oasys Alp, to deliver geotechnical analysis for a transport infrastructure project in Melbourne, Australia. Arup were responsible for the overall geotechnical analysis and design of 11 bored cast-in-place foundations which were required to adhere to Australian building standards.

The project presented several challenges, including varying ground conditions at each foundation location, changing loading conditions, and stringent serviceability criteria related to deflection and rotation.

How Oasys proved invaluable

To overcome these challenges, the team turned to Oasys Alp. Its programming interface, known as the “COM Interface,” allowed the team to interact with the software using scripting. This feature enabled the Melbourne Ground Engineering team to create a spreadsheet that could read and write relevant information to and from Alp seamlessly.

The integration of Alp and its COM Interface streamlined the team’s workflow significantly. The team were able to analyse hundreds of different pile length and diameter options that satisfied the serviceability criteria for each foundation within minutes. The software’s programming interface and robust performance allowed the team to focus on providing efficient solutions rather than spending time on manual model adjustments.

With Alp, the team achieved crucial time savings during the design stages. Iterative design allowed Arupians to analyse at least 50 (single diameter) pile length configurations in under a minute. A typical workflow that takes up to 30 minutes for a standard pile design satisfying strength and serviceability criteria, was reduced to five minutes. This notable reduction in time enabled the team to deliver efficiently engineered solutions without compromising on quality.

The use of Alp in this project demonstrates its invaluable contribution to overcoming complex geotechnical challenges. Its robust performance and seamless integration with other commonly used software optimised the workflow and led to saving the engineers valuable time whilst maintaining quality in the delivery of effective solutions.

We’d like to thank Humza Tariq, Graduate Engineer and Peter Andrews, Associate at Arup, for sharing this work with us.

To learn more about how to implement Oasys Alp into your project workflows, contact us today at [email protected] or visit the product page to find out more.

Want to learn more about how automated workflows can help improve your projects? Read our LinkedIn article ‘Why taking a digital approach for your Ground Movement Assessment projects is the way forward: Streamlining utilities HS2 Euston Station project’.