Software Used on this Project

Project Overview

Arup Structural Engineer Juan Maier took advantage of the COM Interface offered in GSA when working on the multi-billion dollar Marina Bay Sands Integrated Resort in Singapore.

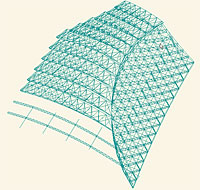

Faced with the challenges of analysing and designing several large steel structures with highly complex geometric form and over 5000 separate elements each, Juan developed a program using the COM Interface to link directly with GSA’s analysis model.

How Oasys proved invaluable

“With large structural models that are highly stiffness driven, finding suitable section sizes that work for every element in the model is actually harder than it sounds”. The program was initially written to find a solution for all the elements in the structure designed to the relevant codes of practice under several different load cases.

The true potential of GSA’s COM Interface was soon realised and Juan was able to customise and tailor the program to the specific needs of this project such that it would run a computer automated numerical algorithm to determine the optimum steel weight of the structure while still conforming to the relevant design standards.

In this particular case, the geometric form was not modified. Instead, through an iterative process, the sizes of the structural elements were continuously substituted, analysed, designed and resized until the structure with the least steel-weight was found.

Not only was this an effective and highly efficient method of managing the data from large structural models, it also offered the design engineers the opportunity to fine tune the steel weight of the structures which saved significant costs for the client.

As Peter Bowtell, Buildings Leader in Australia explained: “3D modelling played a pivotal role in delivering this challenging project in such a short timeframe, allowing work that could’ve taken three years to deliver manually to be completed in just three days. Understanding the structure in three dimensions and determining the right size and forces of each of the structural members was crucial to the project success.” Like this case study, automated programs using the COM Interface can be developed to optimise structures for a variety of purposes such as least-cost solution, least weight solution and fastest procurement. The possibilities are unlimited!

Additional links

"3D modelling played a pivotal role in delivering this challenging project in such a short timeframe"