Software Used on this Project

Project Overview

The Heartburst project involved a unique art installation displayed at a festival in the United States (US) back in August 2023. The structure, designed by OFFICEUNTITLED (OU) in collaboration with Arup, was made entirely of bamboo, a highly sustainable material. The bamboo pavilion structure was approximately 30ft by 30ft in plan and 15ft tall. It was comprised of a series of bamboo rod lattices, with large heart-shaped tunnels cut through its form. There were two main goals for this project: creating a community space for festival goers and to discover the possibilities of designing with a sustainable material, not currently commonly used in North America. Oasys GSA was chosen as the primary structural analysis software as it allowed Arup Engineers the ability to analyse many unique design considerations.

Photo credit: Christian Robert, Architect

Heartburst’s unique geometry and its atypical structural material made for an interesting design process and plenty of challenges. One of the main challenges the team faced was establishing design values for bamboo rods and their connections. The team collaborated with Malaysian engineering firms, JTK Consult and SEAD Build, who performed structural testing of the bamboo elements and their typical connections at the Universiti Teknologi Malaysia. These tests were used to establish material properties and an analysis pathway for the bamboo structure, essentially creating a design code for bamboo in GSA.

Another unique challenge was understanding the appropriate loading for the installation, considering factors such as high desert winds and the potential for people to climb on the installation.

How Oasys proved invaluable

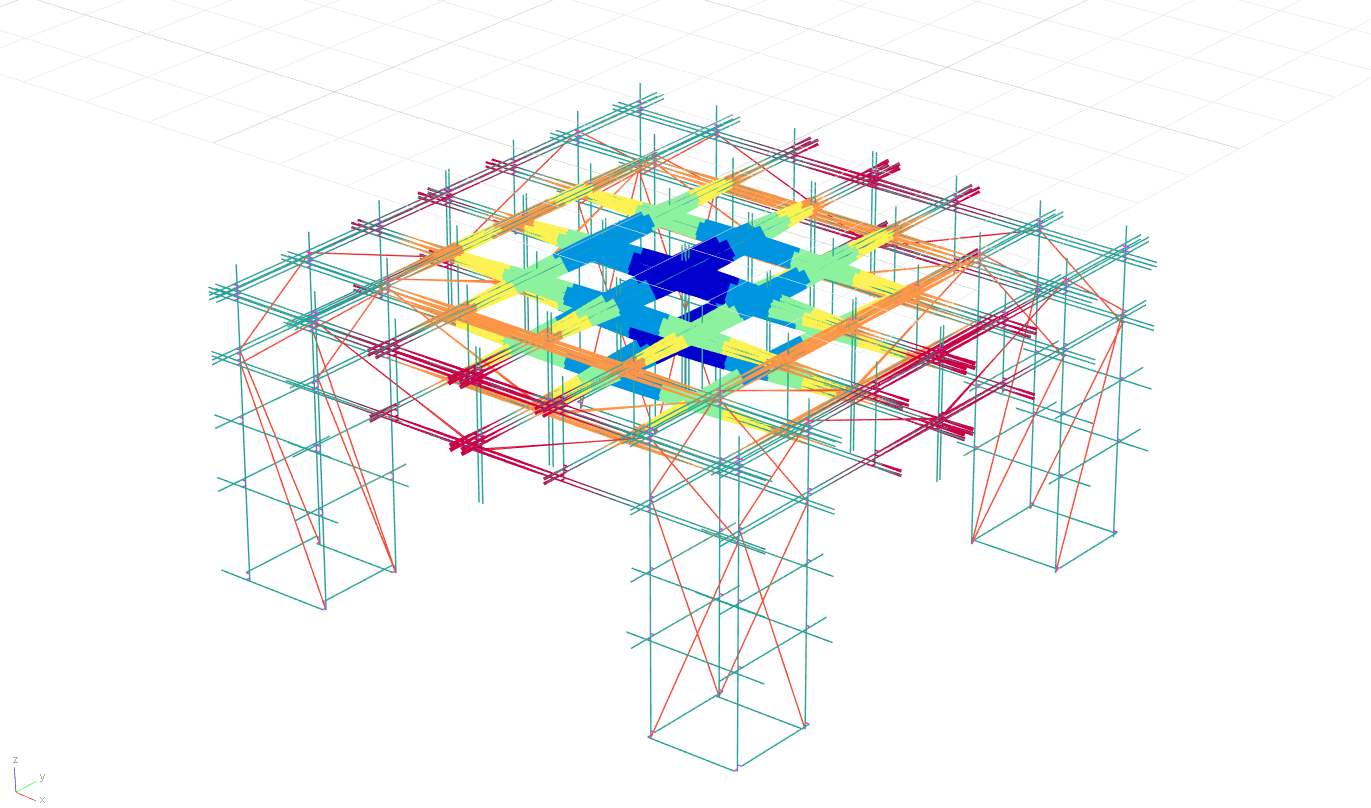

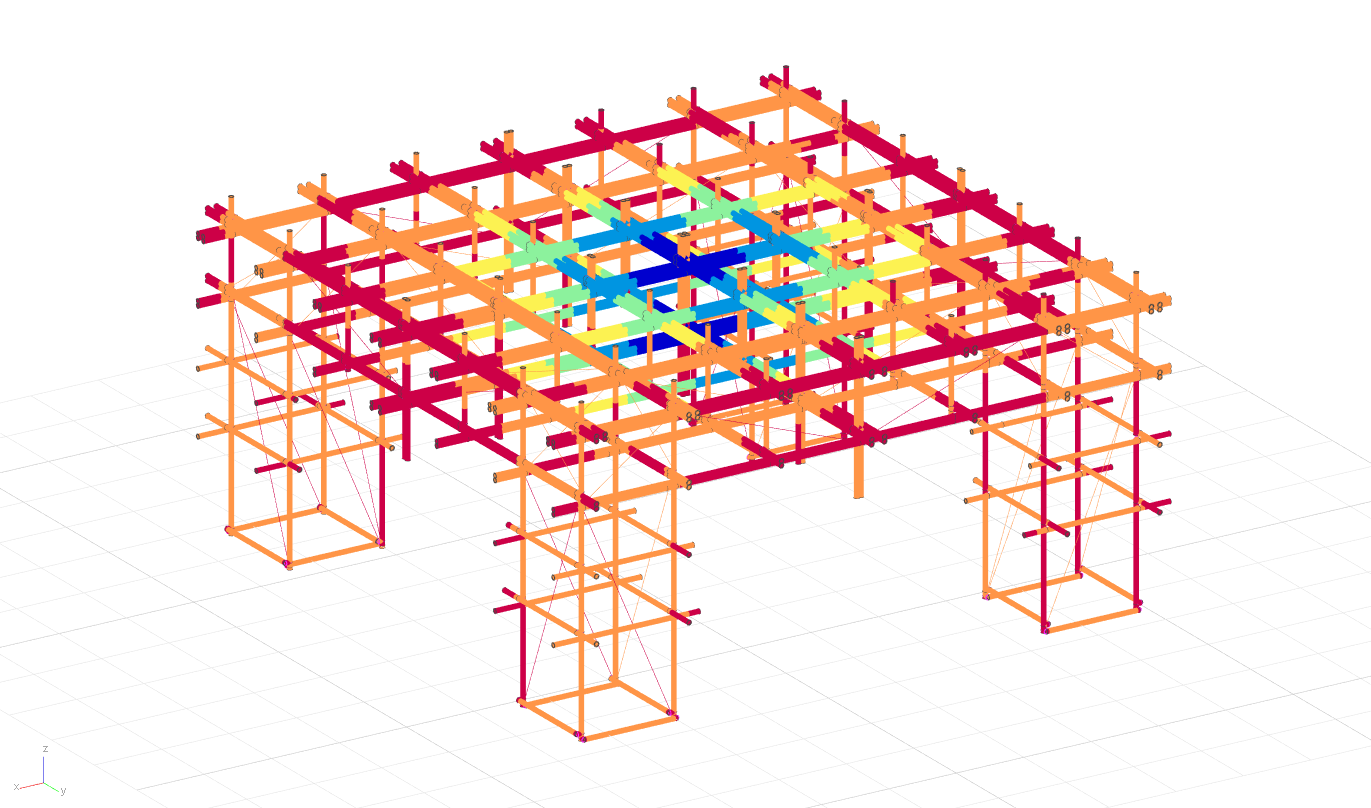

Once a design path was agreed upon, the team used GSA structural analysis software to model and analyse the bamboo pavilion and assess its performance. Using the model, member forces were compared to allowable capacities based on the university test results. A tested bolted connection was used for primary structural connections. A simpler tied connection using rebar tie wire was developed for secondary connections.

© Arup

GSA’s features such as assemblies, custom views, and element customisation were instrumental in helping the team conquer the challenges they faced.

The assembly feature was imperative to the structural analysis of the pavilion. It provided an easy-to-use method for grouping individual elements together aggregating their response to applied demand. The bamboo lattice structure had many bamboo rods placed in close proximity. Using assemblies, the Heartburst team could toggle between individual element response and grouped response to clearly assess loading of the structure.

The Arup team had to iterate the model several times due to communications with external partners. Custom views in GSA made assessing the impact of change a much more efficient process. GSA made it easy to save a view which includes viewport orientation, selected elements, displayed analysis data, and load case/combo. This increased efficiency in analysis between changes in the model.

The element customisation feature in GSA was crucial given the fixed length of the bamboo rods, which meant the structural team had to carefully consider the location of splicing.

© Arup

The Heartburst team highly valued the use of bamboo. The Heartburst eco footprint page reads: “By using bamboo in the construction of the installation, Heartburst promotes environmental responsibility and demonstrates the possibility of creating stunning spatial experiences without causing harm to the planet.”

“Our hope is that Heartburst will continue to demonstrate the integrity and sustainability of bamboo as a structural material. The Heartburst project demonstrated the power of using sustainable materials in construction, promoting environmental responsibility, and creating stunning spatial experiences.” – The Heartburst team.

The use of GSA proved powerful in handling complex structural analysis tasks, making it a crucial part of the structural workflow for the Heartburst team. The team expressed that GSA’s interface is their preferred software for building and assessing unique geometries. This project has also been featured in Amazing Architecture, dezeen and Parametric Architecture.

We’d like to thank the Arup’s Los Angeles based structural team including Design Engineer, Genevieve Graham, Associate Principal, Robert Pallmann and Associate, Toshiyasu Yoza for sharing this work with us.

Find out more about Oasys GSA’s core capabilities here.